Rössing atomic performance

From 1928 to 2019 Rössing Uranium Mine energised Namibian technological development.

AUGETTO GRAIG

Rössing Uranium Mine has a long and distinguished history marking many of the firsts in Namibia’s extensive mining history. Since the early years between 1928 and 1965 when the original prospectors found signs of uranium oxide mineralisation, the company has built on its past to lead Namibia into an atomic future.

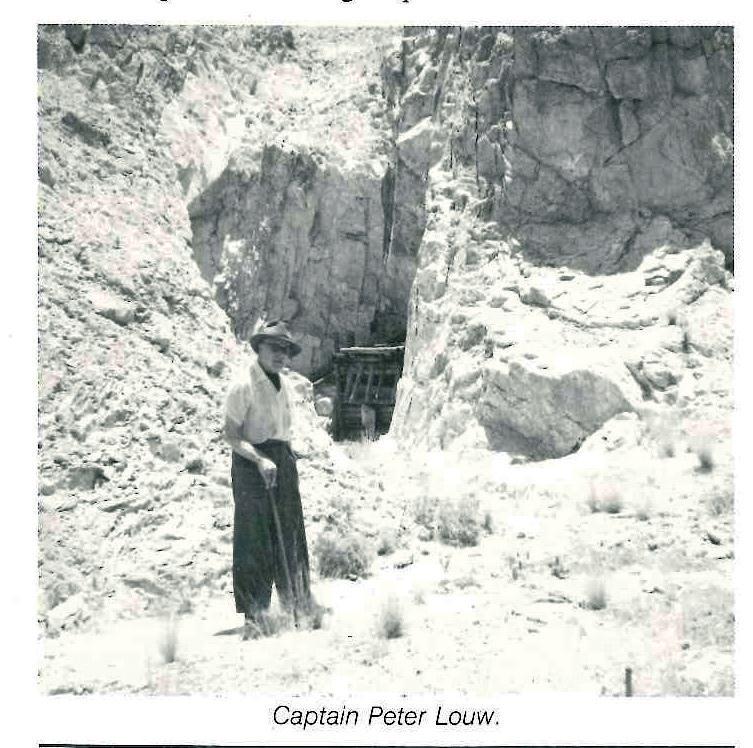

John Louw recently celebrated his 40th year as a Rössing board director in 2012. He is one of the three sons of the geologist Captain Peter Louw, who discovered the first traces of uranium in the Namib Desert, which ultimately led to the establishment of Rössing.

At the occasion Louw recounted how his parents had turned to prospecting in the difficult time before the Great Depression (1929-1934), looking for radium in the desert near Rössing Mountain. Smallish black stone samples were sent to the Teddington laboratory in Britain for analysis but proved to be of no apparent financial value, he recalled.

Later, after the USA ended World War II by dropping atomic bombs on the Japanese cities of Hiroshima and Nagasaki, the world instantly became aware of the awesome power of uranium.

Then a student of industrial chemistry, employed in the laboratories of an energy-conscious petroleum company in Cape Town, Louw began to think again about the small black stones he knew as a boy.

“I understood from the periodic table of elements that uranium could belong to the same family of minerals as radium, and that the presence of radium might well indicate a source of uranium in the area of Swakopmund. Some time later, on a visit to Swakopmund, I discussed my theory with my father and suggested we drive out to the old radium prospecting area of those early years to investigate the possibility of a uranium presence. Somewhat reluctantly he agreed, and early the following morning we set out for what we remembered to be the original site.

“It was time for a cup of tea, so we sat on the ground in the shade of the vehicle and planned our course of action. We would each take an area to either side of the vehicle and search for small black stones about the size of a hen's egg. This we duly did, and when our canvas bags were full - some 20 stones in each - we returned to the vehicle to find out the truth with the aid of a Geiger counter.

“We anxiously checked the first bag, small black stone by small black stone, slowly and carefully. Not a single chirp or beep from the Geiger counter. Only silence. Then we checked the second bag; again, deafening silence from the counter ... until, about five stones from the bottom of the bag, the counter took off in wild excitement. That was the birth of Rössing Uranium Limited: one lonely black stone, not much bigger than a hen's egg,” Louw told those in attendance.

Construction of the Rössing Uranium Mine started with the pouring of concrete for the large mine workshops in July 1974. Over the next two years 30 000 cubic metres of concrete was poured, 2 200 tonnes of steel plate was erected and 15 000 tonnes of mechanical equipment was installed on an isolated spot in the Namib Desert.

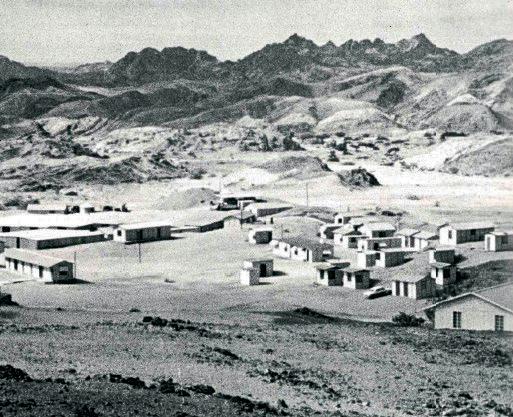

The initial pit development was done between 1974 and 1976 and the pilot plant was constructed. Water supply lines were laid on and a power line was built, destined for Walvis Bay. The town of Arandis took root and houses were added to the Vineta and Tamariskia neighbourhoods in Swakopmund.

By March 1975 the mine and plant were in operation but encountered setbacks due to the abrasive granite rock containing the uranium minerals. Major alterations and additions to the plant cost N$100 million at the time. By February 1980 the product-recovery section boasted the highest production of uranium over 24 hours to exceed the pervious world record.

By October 1987 the electrified innovative spirit at Rössing led to installation and operation of the first 10-percent trolley-assist ramp in the world. Since that first 1 200 volt DC trolley-assist system was installed on the ten-percent-gradient haul roads, the mine has operated its 730E Haulpak fleet successfully.

The immediate benefits of trolley assist are that fully laden trucks accelerate from 11.5 km/h to roughly 17 km/h, shortening the cycle times and increasing the refuelling intervals. Also, engine life is improved as electricity is used to propel the truck, instead of diesel. Lastly, by using electricity, the trade-off between electricity and diesel usage ensures a huge cost saving.

An assessment in early 2016 indicated that the mine would benefit from fast-tracking the relocation of a section of Trolley 13 line, as the tonnage exiting the open pit via Haulroad 17 compared with Trolley 13 was ten times more. The relocation was completed and in December 2016, the fully tested, commissioned and operational Trolley 17 line was handed over to mining operations.

In the years since Rössing came to be, it has continued to chalk up significant firsts for Namibia. The mine has hosted visits from historic figures such as heart surgeon Chris Barnard (1982), British Prime Minister Margaret Thatcher (1989), UN Special Representative Martti Ahtisaari (1989), Founding Father Sam Nujoma and Botswana President Dr Quett Masire (1990), as well as Queen Elizabeth and Prince Phillip (1992).

In 1990 Rössing installed the latest touch-screen technology in its control processing centre and operating station. In 1999 the first of five 182-tonne haultruck pans for Rössing Uranium's new Komatsu Haulpak 730E trucks arrived on site.

On 25 June 1976, the mine produced its 100 000th tonne of uranium oxide. Rössing celebrated achieving nearly three million lost-time injury-free hours in October 2008.

Most recently their latest available annual stakeholders report for 2017 illustrates the mine’s commitment to continued improvement. In 2017 Rössing mined 25.2 million tonnes of rock (3% more than in 2016) of which 9.6 million tonnes was uranium-bearing ore (20% more than in 2016) and 15.1 million tonnes was waste rock removed from the pit (0.5 million tonnes was in-pit dumping). A waste-to-ore strip ratio of 1.57 was achieved, which was significantly lower than in 2016.

Rössing Uranium Mine has a long and distinguished history marking many of the firsts in Namibia’s extensive mining history. Since the early years between 1928 and 1965 when the original prospectors found signs of uranium oxide mineralisation, the company has built on its past to lead Namibia into an atomic future.

John Louw recently celebrated his 40th year as a Rössing board director in 2012. He is one of the three sons of the geologist Captain Peter Louw, who discovered the first traces of uranium in the Namib Desert, which ultimately led to the establishment of Rössing.

At the occasion Louw recounted how his parents had turned to prospecting in the difficult time before the Great Depression (1929-1934), looking for radium in the desert near Rössing Mountain. Smallish black stone samples were sent to the Teddington laboratory in Britain for analysis but proved to be of no apparent financial value, he recalled.

Later, after the USA ended World War II by dropping atomic bombs on the Japanese cities of Hiroshima and Nagasaki, the world instantly became aware of the awesome power of uranium.

Then a student of industrial chemistry, employed in the laboratories of an energy-conscious petroleum company in Cape Town, Louw began to think again about the small black stones he knew as a boy.

“I understood from the periodic table of elements that uranium could belong to the same family of minerals as radium, and that the presence of radium might well indicate a source of uranium in the area of Swakopmund. Some time later, on a visit to Swakopmund, I discussed my theory with my father and suggested we drive out to the old radium prospecting area of those early years to investigate the possibility of a uranium presence. Somewhat reluctantly he agreed, and early the following morning we set out for what we remembered to be the original site.

“It was time for a cup of tea, so we sat on the ground in the shade of the vehicle and planned our course of action. We would each take an area to either side of the vehicle and search for small black stones about the size of a hen's egg. This we duly did, and when our canvas bags were full - some 20 stones in each - we returned to the vehicle to find out the truth with the aid of a Geiger counter.

“We anxiously checked the first bag, small black stone by small black stone, slowly and carefully. Not a single chirp or beep from the Geiger counter. Only silence. Then we checked the second bag; again, deafening silence from the counter ... until, about five stones from the bottom of the bag, the counter took off in wild excitement. That was the birth of Rössing Uranium Limited: one lonely black stone, not much bigger than a hen's egg,” Louw told those in attendance.

Construction of the Rössing Uranium Mine started with the pouring of concrete for the large mine workshops in July 1974. Over the next two years 30 000 cubic metres of concrete was poured, 2 200 tonnes of steel plate was erected and 15 000 tonnes of mechanical equipment was installed on an isolated spot in the Namib Desert.

The initial pit development was done between 1974 and 1976 and the pilot plant was constructed. Water supply lines were laid on and a power line was built, destined for Walvis Bay. The town of Arandis took root and houses were added to the Vineta and Tamariskia neighbourhoods in Swakopmund.

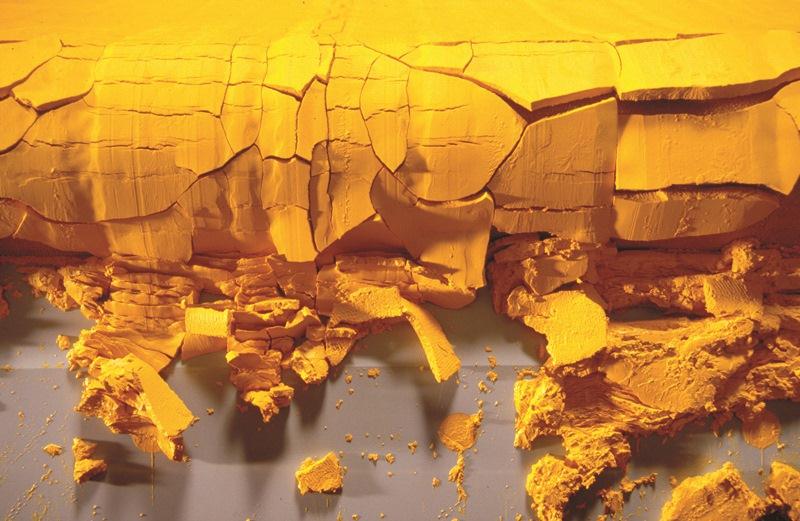

By March 1975 the mine and plant were in operation but encountered setbacks due to the abrasive granite rock containing the uranium minerals. Major alterations and additions to the plant cost N$100 million at the time. By February 1980 the product-recovery section boasted the highest production of uranium over 24 hours to exceed the pervious world record.

By October 1987 the electrified innovative spirit at Rössing led to installation and operation of the first 10-percent trolley-assist ramp in the world. Since that first 1 200 volt DC trolley-assist system was installed on the ten-percent-gradient haul roads, the mine has operated its 730E Haulpak fleet successfully.

The immediate benefits of trolley assist are that fully laden trucks accelerate from 11.5 km/h to roughly 17 km/h, shortening the cycle times and increasing the refuelling intervals. Also, engine life is improved as electricity is used to propel the truck, instead of diesel. Lastly, by using electricity, the trade-off between electricity and diesel usage ensures a huge cost saving.

An assessment in early 2016 indicated that the mine would benefit from fast-tracking the relocation of a section of Trolley 13 line, as the tonnage exiting the open pit via Haulroad 17 compared with Trolley 13 was ten times more. The relocation was completed and in December 2016, the fully tested, commissioned and operational Trolley 17 line was handed over to mining operations.

In the years since Rössing came to be, it has continued to chalk up significant firsts for Namibia. The mine has hosted visits from historic figures such as heart surgeon Chris Barnard (1982), British Prime Minister Margaret Thatcher (1989), UN Special Representative Martti Ahtisaari (1989), Founding Father Sam Nujoma and Botswana President Dr Quett Masire (1990), as well as Queen Elizabeth and Prince Phillip (1992).

In 1990 Rössing installed the latest touch-screen technology in its control processing centre and operating station. In 1999 the first of five 182-tonne haultruck pans for Rössing Uranium's new Komatsu Haulpak 730E trucks arrived on site.

On 25 June 1976, the mine produced its 100 000th tonne of uranium oxide. Rössing celebrated achieving nearly three million lost-time injury-free hours in October 2008.

Most recently their latest available annual stakeholders report for 2017 illustrates the mine’s commitment to continued improvement. In 2017 Rössing mined 25.2 million tonnes of rock (3% more than in 2016) of which 9.6 million tonnes was uranium-bearing ore (20% more than in 2016) and 15.1 million tonnes was waste rock removed from the pit (0.5 million tonnes was in-pit dumping). A waste-to-ore strip ratio of 1.57 was achieved, which was significantly lower than in 2016.

Kommentar

Allgemeine Zeitung

Zu diesem Artikel wurden keine Kommentare hinterlassen